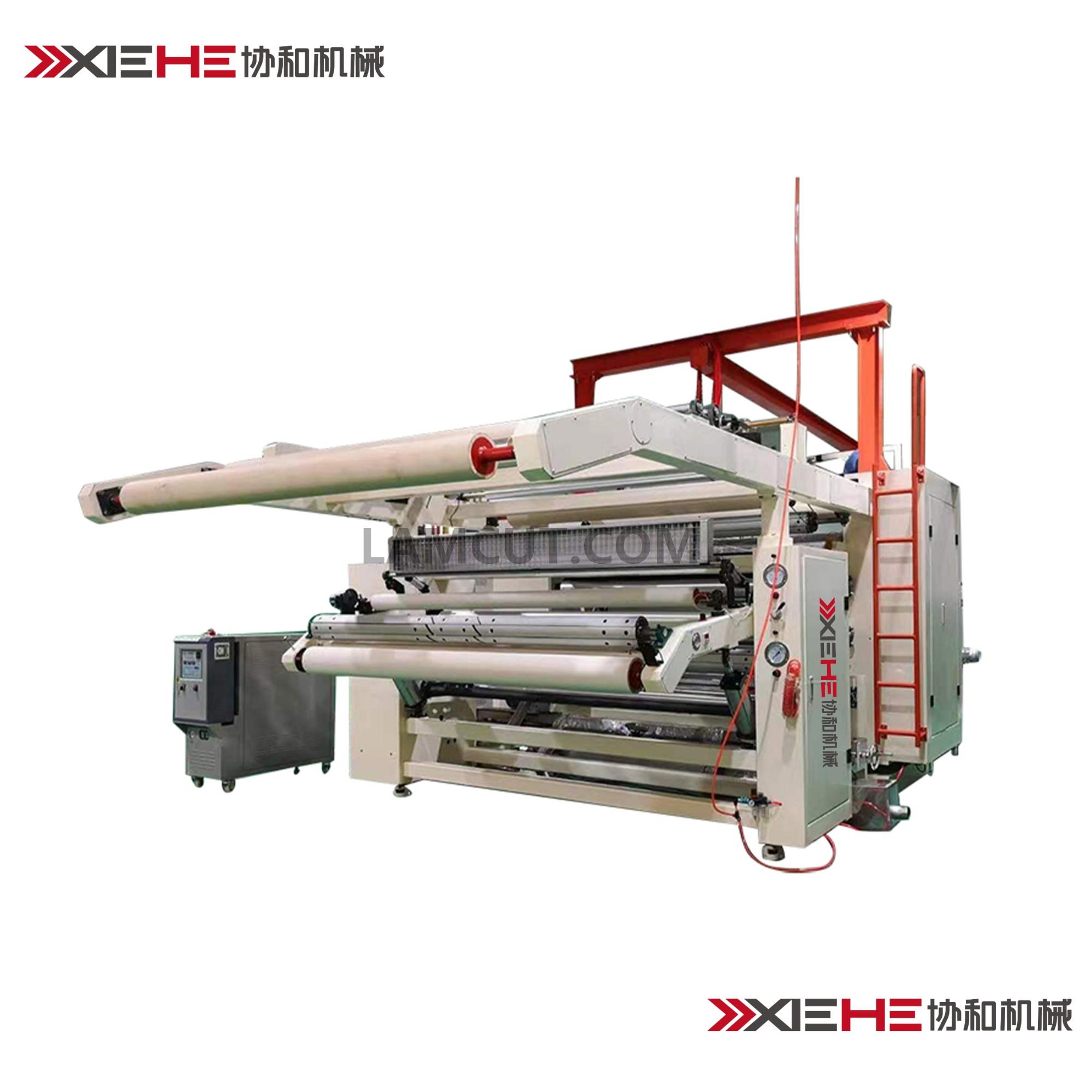

PUR Hot Melt Adhesive Laminating Machine for Textiles

PUR Hot Melt Adhesive Laminating Machine for Textiles

PUR Hot Melt Adhesive Laminating Machine for Textiles is the ideal production equipment for high-end apparel, home furnishings, and technical textiles.Directly contact: sarah@lamcunt.com

Overview:

This machine is a high-precision and high-efficiency hot melt adhesive laminating system specifically designed for the textile industry.It utilizes an advanced PUR (Polyurethane Reactive) adhesive application system. Through precise temperature control, uniform coating technology, and stable lamination pressure, it achieves high-speed and high-strength bonding of two or more layers of textile materials. The final products are characterized by strong adhesion, washability (both water and dry cleaning resistance), soft hand feel, and eco-friendliness (solvent-free). It is the ideal production equipment for high-end apparel, home furnishings, and technical textiles.

Key Features:

1. Efficient & Precise Coating: Equipped with a high-precision comma刮刀 or gravure roller coating system for even and controllable glue application, fine glue lines, and significant adhesive savings.

2. Intelligent Temperature Control: Features a PLC and PID intelligent temperature control system for zonal precise temperature management of the PUR glue tank, hoses, and coating roller, ensuring optimal PUR performance and preventing charring.

3. Powerful & Uniform Lamination: Heavy-duty lamination rollers with a uniform pressure system ensure consistent pressure across the entire fabric width, resulting in bubble-free and wrinkle-free laminates.

4. User-Friendly Interface: Large color touchscreen for intuitive parameter setting. Supports storage of multiple product recipes for quick changeover.

5. High Compatibility & Flexibility: Suitable for various substrates including woven, knitted, non-woven fabrics, leather, and films. Unwinding, lamination, and rewinding tensions are independently adjustable to accommodate fabrics of different weights and elasticity.

6. Safe & Eco-Conscious Design: Fully enclosed melting system effectively prevents premature reaction of PUR adhesive with ambient moisture. Comprehensive safety alarms ensure operational safety.

Technical Specifications :

· Max. Working Width: 1800mm / 2200mm / 2400mm (Optional)

· Machine Speed: 0-30 m/min (Adjustable)

· Coating Method: Comma刮刀 / Gravure Roller

· Heating Method: Electric / Thermal Oil

· Total Power: Approx. 45 kW

· Control System: PLC + Color Touch Screen

· Overall Dimension: Approx. L12000 x W3000 x H2000 mm

Applications:

· Fabric lamination for down jackets, outdoor wear, and functional garments.

· Lamination of automotive interiors and furniture upholstery fabrics.

· Fabric bonding for footwear and luggage.

· Lamination of technical textiles such as medical protective clothing and filtration materials.

INQUIRY

Categories

Contact Us

Contact: Sarah Qi

Phone: 15189245666

E-mail: sarah@lamcut.com

Whatsapp:+8615189245666

Add: No.1 East Chengxiang Rd,Dagang Town,Yancheng,Jiangsu,China