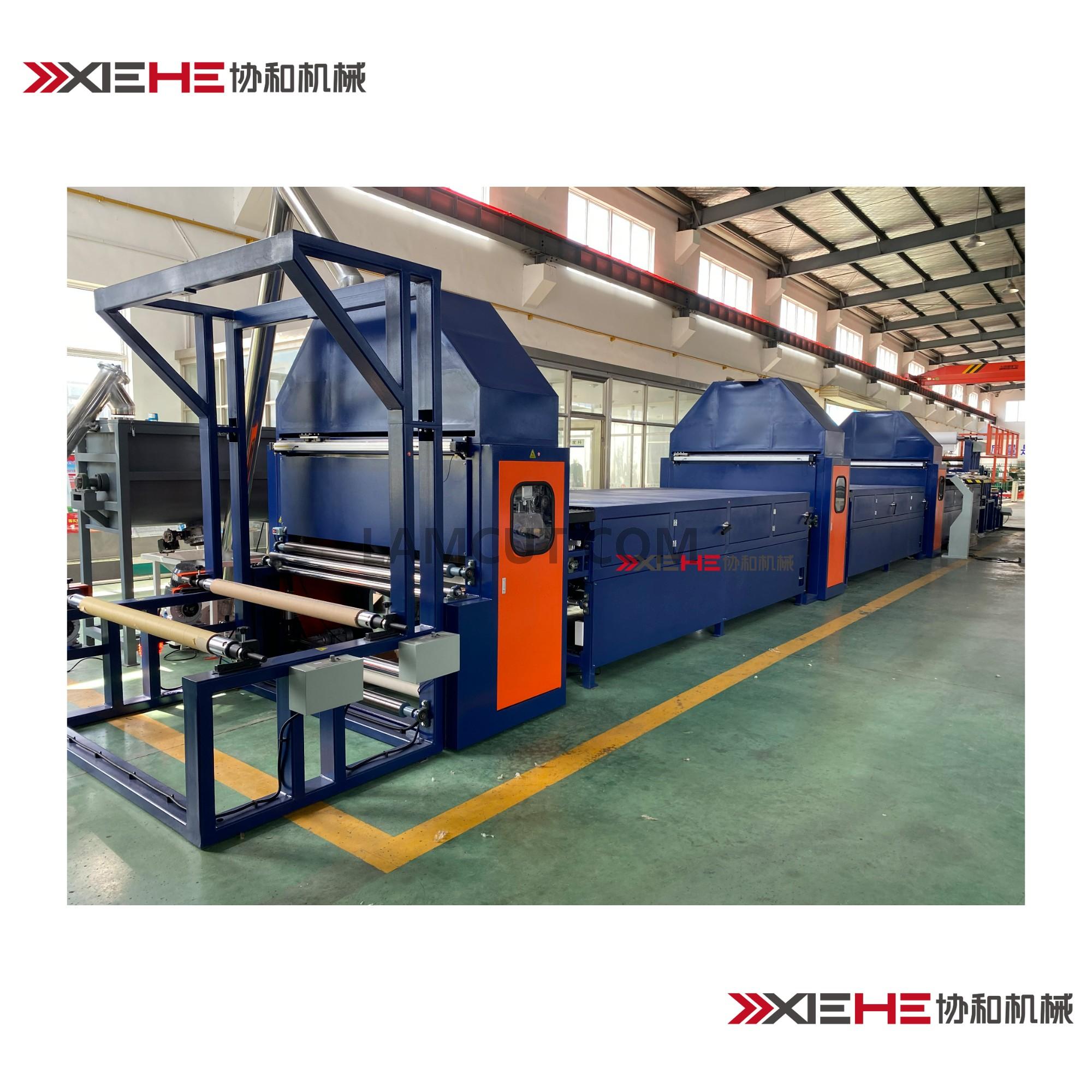

Acticated carbon powder scattering laminating machine-Air filter

Acticated carbon powder scattering laminating machine-Air filter

Acticated carbon powder scattering laminating machine-Air filter,mainly serving industries such as mixing, spreading, and lamination processes of carbon powder (activated carbon powder) and hot melt adhesive powder in fields such as automotive air filters, industrial filters, and special filter materials.Directly contact: sarah@lamcunt.com

Purpose:

The activated carbon powder scattering lamimnating machine is designed specifically for products in the automotive air filtration industry that have special requirements for dust adsorption, such as air filters with carbon powder layers. It can efficiently and accurately spread a mixture of carbon powder and hot melt adhesive powder evenly on non-woven fabrics, meltblown fabrics, and other substrates, and form strong and functional composite materials through hot pressing and compounding. The equipment has the characteristics of high precision, high efficiency, environmental friendliness, cleanliness, and easy operation.

Main applications: Mixing, spreading, and lamination processes of carbon powder (activated carbon powder) and hot melt adhesive powder in fields such as automotive air filters, industrial filters, and special filter materials.

technological process:

Roll up → Powder spreading → Heating curing → Laminating → Roll up

Features:

1. Adopting an imported temperature control system to ensure a constant temperature in the drying oven, with a temperature difference of less than ± 2 ℃, to ensure stable product width;

2. Adopting a special heating system, it heats quickly and ensures stable hot melt effect;

3. Adopting energy-saving and energy-saving insulation oven to prevent temperature loss;

4. The stirring and vibration system of the powder spreading head ensures uniform powder spreading on the surface of the material;

5. The transmission adopts a frequency conversion synchronous control system to ensure that the vehicle speed is synchronized with the powder spraying, so as to control the powder spraying amount evenly and stably.

6. The mechanical width is customized according to the material width.

7. Cooling method: Water cooling or air cooling can be used.

INQUIRY

Categories

Contact Us

Contact: Sarah Qi

Phone: 15189245666

E-mail: sarah@lamcut.com

Whatsapp:+8615189245666

Add: No.1 East Chengxiang Rd,Dagang Town,Yancheng,Jiangsu,China